Capstone Project Addresses Power System Protection and System Reliability

June 26, 2023

The Department of Electrical and Computer Engineering’s capstone design teams are always looking for projects to solve real-world problems, and one team recently tackled a way to bridge gaps in electric grid reliability.

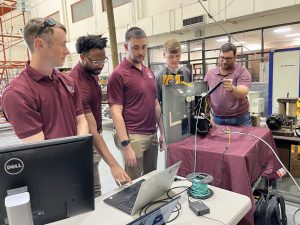

Gear-EM Actuated Relay is a project that team members Adam Eades, Cooper Hollomon, Paten Junkin, Zack Stout and Noah Wright created over ECE’s two-semester capstone project. Geomagnetic Electromechanical Actuated Relay (GEAR) blends the trusted and traditional methods of line protection with the next generation of features.

Gear-EM Actuated Relay team members (left to right) Adam Eades, Noah Wright, Zack Stout, Paten Junkin, and Cooper Hollomon demonstrate GEAR’s uses

The industry currently utilizes two protective relaying systems, electro-mechanical and microprocessor based. The capstone project takes the electromechanical relay and adds the microprocessor features so that even if the microprocessor functions fails, the relay will still operate and protect the system.

Recent electrical engineering graduate Cooper Hollomon said his team became interested in enhancing power grid operations and reliability based on what they learned from the team’s faculty advisor, David Wallace, an ECE assistant clinical professor and the Paul B. Jacob High Voltage Laboratory (HVL) manager.

“Inspiration came from Dr. Wallace’s article on geomagnetic storms and the stunning lack of integration from the still common electromechanical relays. He was a huge influence on our project, from his wealth of industry knowledge to his facilities that he was gracious enough to let us use,” Holloman said.

Wallace noted the senior design projects help students apply their knowledge to real-world challenges, and it helps provide hands-on experience that translates to industry partners. He said this project would be of interest to all of the electrical utilities, co-ops and companies.

“These projects give the students the opportunity to see a problem that exists and come up with a viable solution for it. This fits nicely into what students will experience in the real world. When our graduates take a job, they will be expected to have the skills to troubleshoot a problem and come up with a solution to it,” Wallace said.

By adding a new suite of features to the classic electromechanical relay, GEAR provides a new standard for power system protection and increases system reliability to new industry standards.

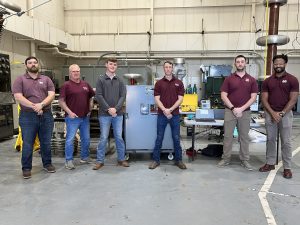

GEAR team members with advisor Dr. David Wallace.

“GEAR adds these features to older electromechanical relays, while also encasing them in a protective enclosure to enhance the resilience of protection against the geomagnetic storms – aiding in the ability to restore power to end customers quicker,” Wallace added. “Older electromechanical relays cannot be reset remotely or monitored for numerical values of faults, so GEAR adds these features.”

Cooper, who graduated in May and is an Area Engineer with Tennessee Valley Authority, said his work on the project has provided invaluable experience, especially since they have been able to work in the department’s HVL and with power industry partners through the process.

“The HVL is a huge component to MSU and is a reminder that State remains a juggernaut in the power community,” Cooper said.

To learn more about ECE’s Paul B. Jacob High Voltage Laboratory visit its website.

To learn more about Wallace, visit his faculty page.

The Department of Electrical and Computer Engineering at Mississippi State University consists of 27 faculty members (including seven endowed professors), seven professional staff, and over 700 undergraduate and graduate students, with approximately 100 being at the Ph.D. level. With a research expenditure of over $14.24 million, the department houses the largest High Voltage Laboratory among North American universities.